| Place of Origin: | China |

| Brand Name: | TOBO |

| Certification: | ISO |

| Model Number: | SS316L, 304 |

| Minimum Order Quantity: | 10 PCS |

|---|---|

| Packaging Details: | Plywood wooden cases |

| Delivery Time: | 7work days |

| Payment Terms: | D/P, T/T, Western Union |

| Supply Ability: | 30000PCS |

| Flange Standard: | ANSI B16.5 ANSI B16.47 A/B | Service: | For Oil And Gas Pipeline Sealing |

|---|---|---|---|

| Pressure: | 150lb 300lb 600lb 900lb 1500lb 2500lb | Gasket Standard: | B16.20 |

| Specification: | 1/2"-64" | HS Code: | 8484100000 |

| Highlight: | SS316L Spiral Wound Gasket,ANSI B16.5 Spiral Wound Gasket,300lb Spiral Wound Gasket |

||

Spiral Wound Gasket SS316L, 304 CS 150#, 300#, ANSI B16.5 ANSI B16.47 A/B

Spiral Wound gaskets, ASME B16.20 Metal Gasket

Spiral Wound Gasket,ASME B16.20 Metal Gasket for 150#, 300#, 600#,900#,1500# and 2500# flanges

Ring Joint Gasket, ASME B16.20 Metal Gasket for 150#, 300#, 600#,900#,1500# and 2500# flanges

ASME B16.20 Metal Gasket Material available: CS/304/304L/316/316L/321/347... all steel family

The concept of spiral wound gasket construction was originated by Flexitallic in 1912, inaugurating the beginning of a new era in safe, effective sealing. The primary purpose for this development was the increasingly severe temperatures and pressures used by U.S. refinery operators in the first half of the century.

The necessity for a gasket to have the ability to recover cannot be over emphasized. The effects of pressure and temperature fluctuations, the temperature differential across the flange face, together with bolt stress relaxation and creep, demand a gasket with adequate flexibility and recovery to maintain a seal even under these varying service conditions. The Spiral Wound Gasket is the precision engineered solution to such problems, meeting the most exacting conditions of both temperature and pressure in flanged joints and similar assemblies and against virtually every known corrosive and toxic media.The spiral wound gasket meets the most exacting conditions of both temperature and pressure in flanged joints and similar assemblies and against every known corrosive and toxic media.

ASME B16.20 which covers spiral wound gaskets requires the use of solid metal inner rings in: Pressure Class 900, nominal pipe sizes 24 and larger, Pressure Class 1500 from nominal pipe sizes 12 and larger, Pressure Class 2500 from nominal pipe sizes 4 and larger and all PTFE filled gaskets. In the same standard is also described how a spiral wound gasket should be characterized, below you will find a image on it.

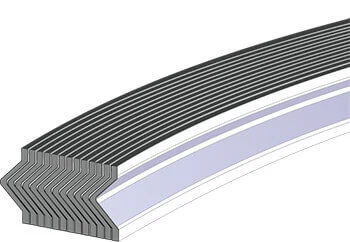

Basic construction type, inner and outer diameters are reinforced with several piles of metal without filler to give greater stability and better compression characteristics. - Suitable for tongue and groove, male and female or grooved to flat face flange assemblies.

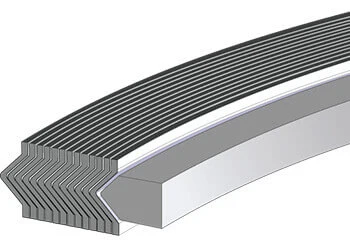

Solid inner metal ring acts as a compression stopper. To prevent accumulation of solids, reduce turbulent flow of process fluids and minimize erosion, damages of gasket between flange bore and the inside diameter, the annular space is filled up by solid inner metal ring. - Suitable for male and female pipe flanges.

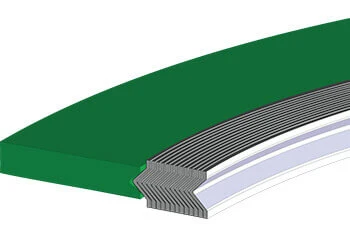

Solid outer ring accurately locates the gasket on the flange face to give the additional radial strength to prevent the gasket blowout and acts as a compression limiter. In case of installing the outer ring, it is very easy to install the gasket to flange face because the end of outer ring will touch at bolts - Suitable for use with flat face and raised face flanges. For class 900 and above an internal ring is recommended.

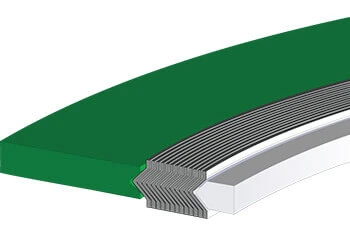

Inner & Outer Rings Type

Typical Applications

Pipe, valve, pump, thermal exchange, condensing tower, plain hole and man hole of flange, etc. Petrochemical, chemical, mechanical manufacturer, power station, metallurgy, shipbuilding, medical and pharmaceutical unclear power station and navigation, etc.

Material

| Structure | Hoop material | Filler material | Inner&outer ring material | Normal thickness(mm) | |

| Gasket | Inner&outer ring | ||||

| Without rings | SS304(L);SS316(L) | Graphite | SS304(L);SS316(L) | 3.2mm | 2.0mm |

| Carbon steel | Aebestos | Carbon steel | |||

| With outer ring | SS321;SS317L | Non-asbestos | SS321;SS317L | ||

| Monel;Inconel | Mica | Monel;Inconel | 4.5mm | 3.0mm | |

| With Inner ring | Titanium;Nickel | Tef lon | Titanium;Nickel | ||

| Duplex 31803 | PTFE | Duplex 31803 | |||

| With inner&outer rings | Hastelloy | Ceramic tape | Hastelloy | 6.4mm | 4.0mm |

| SS347,etc. | etc. | SS347,etc. | |||

Contact Person: Ellen

Tel: 15821287672

Water Oil Base Gas Cast Steel SS 3 Way Ball Valve Flanged End Full Port Ball Valve

Stainless Steel Floating Ball Valve Three Way Simple Structure Easy Operation

4 Way Ball Valve SS316 Body / Ball / Stem PTFE seats Flange ANSI Class 150 Ball Valve

CF8 1.6MPa 2 Inch Stainless Steel Gate Valve , Class 150 Flange End Manual Gate Valve

SS304 DN100 PN16 Stainless Steel Gate Valve Powder Coated

ASTM A126 1" 175 PSI Rising Plug Valve 10000 PSI H Series Flanged Plug Valve

SS304 3/4'' 150LB Manual Globe Valve , Flanged Globe Valve Stainless Steel

1/2'' 150LB Manual Stainless Steel Globe Valve Flange End SS304 A351 CF8 Globe Valve

High Temperature WCB Globe Valve , 3/4'' 150LB Flange End Carbon Steel Globe Valve